Analysis of the clutch slave

cylinder action, bore scoring, and substantiation of the SwEm O’ring upgrade.

02-2005-R.Kwas

--------------------------------------------------

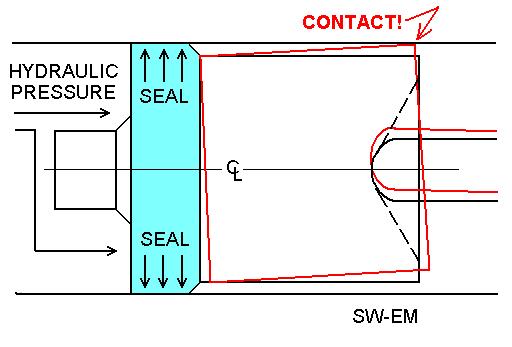

Before hydraulic pressure is translated into any movement of the piston along the bore against the resistance of the actuating rod, all mechanical clearance in line, present when the linkage is in a relaxed state, will first be taken up. One of these clearances occurs inside the slave cylinder assembly, and is caused by the slight difference in the bore ID and the piston OD. It is I believe, a major, if not the predominant cause of scoring of the soft slave cylinder bore.

As the in-line clearances are taken up and before moving along the bore, the “dry-end” of the hard piston will first cock to the side within the bore (because cocking to the side is easier than moving against the resistance of the rod, the action is similar to combustion chamber piston skirts slapping cylinder walls). It will move to the side until it makes contact with the bore, or worse, push any dirt present into the bore. Only then will hydraulic force start to move the piston down the bore.

Only the “dry-end” cocks to the side, because of the fairly high concentric forces developed against the bore by the seal serve to keep the “wet-end” of the piston concentric in the bore, and from making contact. For a standpoint of cutting the bore, this is a pretty good setup, further aided by any dirt, which may have gotten past the imperfect dust-boot. And since the mechanical system is under compression force for the entire time the system is under pressure, the “dry-end” will stay cocked in the bore, grinding any grit present into the bore during its entire movement. This is consistent with the longitudinal scoring which is typically discovered upon disassembly. The longitudinal scoring is also what causes the leakage and is the reason the slave needs to be removed for service in the first place...it is also the kiss of death for the bore.

The cocking effect also puts additional strain on the seal which has to deal with this movement as it expands outward. The seal would be better off doing without this additional duty being demanded of it. If it only had to make expanding, but concentric sealing force without additional compliance forces to keep up with the cocking piston the seal would last longer.

Clutch Cylinder, Before

Whatever it is caused by, whether a fluid breakdown or crystallization of the fluid once it absorbs moisture, I am convinced that the semi-transparent, semi-crystalline gel/grit (which I've seen growing on hydraulic clutch components) is not substantial or hard enough by itself to cause scoring.

It is therefore my assertion, that the (“dry-end”) of the piston cocking against the soft bore is the predominant cause of internal scoring.

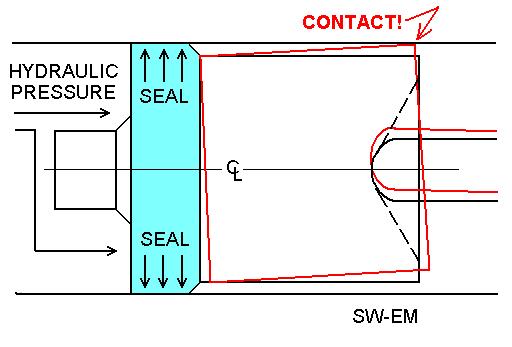

With this in mind, I decided to do the same thing at the “dry-end”, as at the “wet-end” (keep it centered and from making contact). It’s quite simple really! With an O’ring! An O’ring, located in a groove at the “dry-end” serves to keep the piston concentric in the bore, and also excludes dirt. In industry, where the importance of keeping pistons concentric in a bore has long been recognized, but dirt is less of a concern, Teflon rubbing blocks which set into holes, spaced evenly around the piston and are slightly proud of the piston surface, are sometimes used for this purpose.

If there is no foreign debris and no contact of piston to bore, there will be no scoring of the bore, EVER, and no resulting degradation of the seal. This is why I am convinced that with an O’ringed piston is a great way for a brand new slave cylinder to start its service life. The observant reader might call the O’ring a second seal...that may be, but this is not its' primary function...it might be considered a secondary function, and there's nothing wrong with that either! In any case, combined with silicon fluid, I expect a huge increase in the service lifetime over the often disappointingly short times between rebuilds. My own experience so far has proven this out on several vehicles. Life is good!

Clutch Cylinder, After

--------------------------------------------------