Heat from Heater/Defroster, when Control is set to COLD

First published Jun 2023 R.Kwas, Revisions ongoing! [Comments Added]

This subject comes up repeatedly, especially as our cars get older.

Bowden Cable Action

at Heater Control Valve

Heater Control Valve Fully Closed

Heater Control Valve Fully Open

Problem Condition

The Simple Fix - Barbing the Sheathclamps

Reference Information

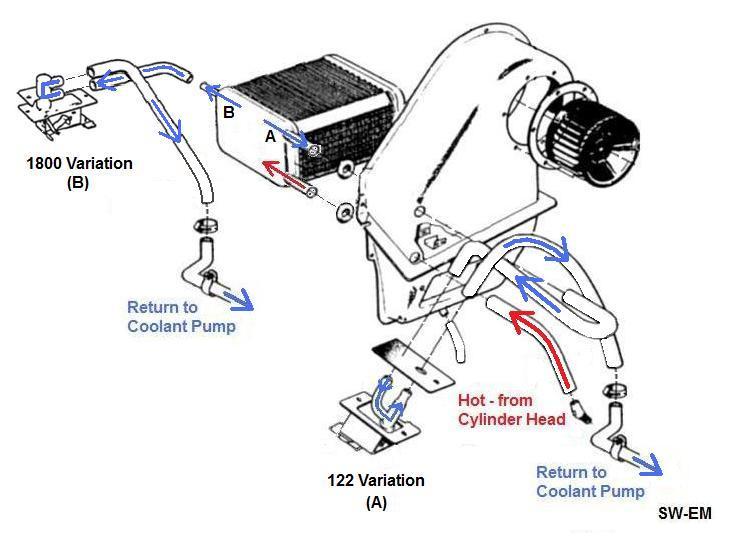

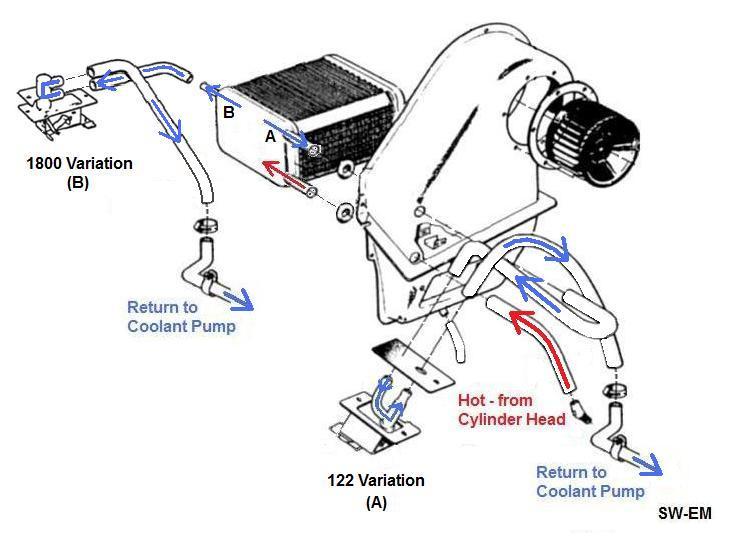

Heater Core Circuit

Cold Flow or Creep

Bowden Cable info

"Other Solutions" to Slipping

Bowden Cable Sheaths

Note:

The info here is also directly applicable to the Choke

Bowden Cables. See:

https://www.sw-em.com/checkchoke.htm

...as well as even the Fresh-Air Vent Controls on all the 1800 Sport models.

See:

https://www.swedespeed.com/threads/cold-air-vents.685881/?post_id=8289354#post-8289354

...this thread includes a nice video showing how smoothly and effortlessly these

parallelogram control linkages can be made to function once again, with not much

more than just refurbishing and lube!

---------------------

The Heater Control Valve is located on the firewall above the parcel shelf in

the passengers Footwell of vintage Volvos (L/RHD Amazon), with its plumbing protruding through the mounting

surface into the engine compartment, and its linkages in the passenger

compartment.

Heater Control Valve in Situ in a 122, as viewed in Passenger Compartment footwell, with

black Bowden

Control

Cable

departing to Heater Control Panel, and Copper capillary heat sensing tube departing

downwards toward Airbox.

Shown in the fully closed position, this

is what it should look like when the Temp Control is set to Cold! If more

of the Sheath

of Bowden Control Cable is visible below Sheathclamp, you have found the

commonly occurring reason you are getting Heat

when Control is set to Cold!

Bowden Cable

Action at Heater Control Valve:

In normal operation, a

Bowden Control Cable from the Heater Control Panel

imparts about 1 inch of movement to the Actuation Lever of the Heater

Control Valve. When Control Cable is fully extended, the

valve is closed and Coolant flow through the HCV is blocked. When Control Cable is fully

pulled, a linkage lifts Coolant Seal from its seat, opening valve and allowing flow.

A Helper or Return Spring on the Ranco H16 Valve

aids with returning the linkage position when opening the valve.

Heater Control Valve Fully

Closed:

HCV with Actuating Lever shown in the fully Closed position. Note

AL angle and, and that it is

up against the lower stop! No

coolant flow is allowed through Valve, so no heat can be exchanged in Heater

Core! Note also that in the normally and correctly installed position, the

Control Cable Sheath protrudes between

1/4" and (no more than) 1/2" past the clamping area.

Heater Control Valve Fully

Open:

HCV with Actuating Lever in the fully Open position. Note

AL angle and, and that it is

up against the upper stop!

Coolant is allowed to flow through Heater Core

Circuit, and can keep us (or Windshield) toasty!

Note that the Return Spring is now stretched and will "help" to

move the AL and close the valve mechanism...but notice also, that the mechanism is not free enough to move with

only the force of return spring. Even though well lubed (with graphite

filled grease), and smooth to operate, the linkage of the sample HCV shown here

had enough resistance to movement, so maintained its open position without input from

the control cable!

Problem Condition:

A slipped sheath has occurred!

Sheath has slipped in it's Clamp

and input motion is lost. Although Cable is almost fully pulled, instead

of imparting all of the motion to the control lever, it's motion has served to

move the Sheath from its proper position! The HCV actuating lever is only partially

activated, so remains at mid-travel,

and linkage is clearly not in contact with the

linkage stop!

When this situation occurs in the car, Temp Control may very well be set to Cold, but

since HCV is not fully closed, some engine temperature Coolant is still allowed to continue to flow through Heater Core Circuit, and warm air results!

[Including even if no airflow is

selected, just by the heated air sneaking around the less than perfectly closed

flaps of the Airbox!] This is the typical

Problem Condition resulting in less than full motion of the Actuating Lever at the HCV, and

producing heated air, when we would rather not have it...like in the summer! It

should be clear to the reader that if Sheath slips at either sending

end...(Heater Temp Control) OR receiving end (HCV), of the Bowden Cable, this condition can occur,

resulting in less than full movement of the HCV actuating lever!

The Simple Fix - Barbing the Sheathclamps:

As rubber outer covering of Bowden Cable ages, and is subjected to continuous

pressure from the Sheathclamp, it

Cold-Flows ...Sheathclamp can, and

typically looses its grip,

allowing Sheath to slip, resulting in lost motion and the above Symptoms.

Corrosion inside the Bowden Cable (which increases friction between inner Cable and

Sheath) also contributes to the condition, so this is a not infrequently

occurring age-related

issue.

To prevent this, and return the function to proper and as-new, it is a simple

matter of increasing the holding power of the Sheathclamp, and reducing the

cable friction...Barbing your Sheathclamps, and lubing your cables!

Step 2 of the author's preferred way to prevent control cable sheath

slippage: Dimpling and Barbing the Sheathclamp! Clamp is removed

from it's assembled location (both input, at Heater Control Panel, and output termination

at HCV should be so treated!), holding it securely in a vice, then using a

center punch, making a series of dimples, moving some of the soft clamp material

into a dimple with an adjacent sharp Barb. This increases the holding

ability of the clamp immeasurably, such that in combination with Step 1. Permanent

lubrication of the Bowden Cable!...the control will feel and move soft as silk

once again,

and all control inputs will be translated to full movement at the receiving end...and that forevermore! Gosh, I do nice work!

-----------------

My response to yet another (this time on

),

posting of Heat/Defrost System continuing to give Heat, when Control is set to

COLD, and Heater Control Valve should be fully

closed and allow NO heated engine Coolant to flow through Heater Core...then

some helpful poster suggests replacing the HCV...

),

posting of Heat/Defrost System continuing to give Heat, when Control is set to

COLD, and Heater Control Valve should be fully

closed and allow NO heated engine Coolant to flow through Heater Core...then

some helpful poster suggests replacing the HCV...

"BEFORE suggesting OP replace the Heater Control Valve, he should simply

assure that all Bowden Control Cable action of the control, when set to Cold, is

getting to the HCV! Typically it is not!

Hubert [OP], I suggest you set

the Temp Control to Cold while watching the action of the Bowden Cable directly

at the HCV linkage (located in passenger side footwell...follow Control Cable!)

, then try to move the linkage at HCV further in that direction (to fully close

it!). If the HCV linkage can be moved further, then there is Lost Motion, and

not all the action you put in at the Control is getting to the HCV, so it is

staying partially open, and you keep getting heat from the Heater Core!

This is quite the typical symptom of a slipping Bowden Cable Sheath, which can

easily be remedied by barbing the Sheathclamps at both ends, and also lubing the

cable. See:

https://www.sw-em.com/checkchoke.htm#appendix_2

Also: https://www.sw-em.com/Heater_Control_Valve.htm Good Hunting "

------------------

Reference Information:

Heater Core Circuit:

Coolant flow at Heater Core and

Heater Control Valve.

122 and 1800 plumbing variations are shown.

Source:

https://www.sw-em.com/Cooling_System.htm#heating_/_defrost_systems

Cold Flow or Creep:

The popular reference source calls the physical property of materials, to

slowly deform because of the constant force they are subjected to:

"Creep".

I prefer to use the more scientific term of "Cold

Flow" and reserve the term Creep for other things...

...nice "3qt pot" haircut bud...!

Bowden Cable info:

See also: Bowden Cable use in Volvo Choke:

https://www.sw-em.com/checkchoke.htm#Reference_Information

See also:

Bowden Control Cable

...on the popular reference site.

While surfing restoration of other vehicles...I ran across this tidbit of

applicable info: In this case, a 1953 KR175 Messerschmitt Kabinenroller

three-wheeler, being restored by an interesting young German man who normally

concentrates on the Italian Piaggio Apecars (also three-wheelers), the Bowden

Cables are used in a slightly different way...

Source:

https://www.youtube.com/watch?v=Qp50EuS9S9E

In the brakes of a Messerschmitt KR175 three-wheeler, Bowden Cables remain

fixed, and Sheaths are intentionally moved, rather demonstrating

that that it is the relative movement of the two which is important

to transfer input action to the receiving end. It may be a bit difficult

to make out on the above frame-capture, but the Cables are indeed terminated on

a non-moving end-stop at Green,

and the Sheaths are connected to the moving Brake Pedal

(at Yellow)!

Voiceover Excerpt: " ...man schiebt/zieht nicht wie normalerweise die

Seilzüge, mann shiebt die Huellen quasi, um für Bremsen zu sorgen..."

Author's Translation: "...one does not push/pull the (Bowden) Cables,

one pushes the Sheath, to activate the brakes..."

---------------------------

"Other Solutions" to Slipping Bowden Cable

Sheaths:

Below is shown the condition this owner found his heater control cables in,

all of which had slipped. One Sheath is uncaptured, still hanging in

the breeze, resulting in ALL motion being lost, with none being transferred, and

two others exhibiting creative attempts at improving the Sheathclamp holding

ability...one by adding an 8(est.) penny nail, one by wrapping Sheath with alu

foil...

I prefer the less-rustic (and completely indivisible-and stealth!) method of

simply barbing the Sheathclamp...

Crop of a William S. pic, used with his kind permission.

Rustic solutions to slipping Bowden Cable Sheaths...

--------------------------------------------------------

External Info Sources are attributed. This article is Copyright © 2024. Ronald

Kwas. The terms Volvo, and Ranco are used for reference only. I have no affiliation with

any of these companies other

than to try to keep their products working for me, help other enthusiasts do the

same, and also present my highly opinionated results of the use and care of their

products here. Working on the Cooling System will in some cases involve

working in close proximity to Hot or Moving components! Reminder:

Work Carefully to avoid Injuries or Damage! The information presented comes from my own

experience and carefully considered opinion, and can be used (or not!), or

ridiculed and laughed at

around the Watercooler (or worshipped!), at the readers discretion, but must

be used in conjunction with normal, cautious shop practice. As with any recipe,

your results may vary, and you are, and will always be, in charge of your own

knuckles, and future!

You are welcome to use the

information here in good health, and for your own non-commercial purposes, but

if you reprint or otherwise republish this article, you must give credit to the

author or link back to the SwEm site as the source. If you don’t, you’re just a

lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if

you can supply corrections, or additional objective information or experience, I

will always consider it, and consider working it into the next revision of this

article...along with likely the odd metaphor and possibly wise-a** comment.